Shockwatch Labels, Clips & Tubes

These innovative, proprietary ShockWatch devices contain a tube filled with red liquid held in suspension. When the device is subjected to an impact exceeding a specified G-level, the shock disrupts the surface tension of the liquid, releasing the highly visible red dye into the length of the tube — creating a permanent and immediate indication of mishandling. Normal movement or road shock won’t affect the device — it is only activated by the specific impacts for which it is designed. Once activated, the device cannot be reset.

Available in label, clip, or tube form, these devices can be affixed to product packaging, directly onto the product itself, or incorporated into the product design, giving you the flexibility to prevent damage on virtually any goods requiring care during shipping and handling. Use the ShockWatch Labels, Clips, and Tubes to conduct quality assurance inspections designed to promote zero-defect shipping. By monitoring your goods, these devices can be used to prevent warranty abuse.

As an education tool, these products can influence the behaviour of handlers during the manufacturing and shipping process. They can also aid in ensuring product integrity and serve as a testing mechanism in comparing packaging.

Click here for a ShockWatch label selection guide

ShockWatch Labels

Label: Available in five sensitivities, as indicated by the five different colours — simply match the sensitivity of the Label to the level of impact the product and packaging can withstand. Activation indicates an impact beyond the predetermined level.

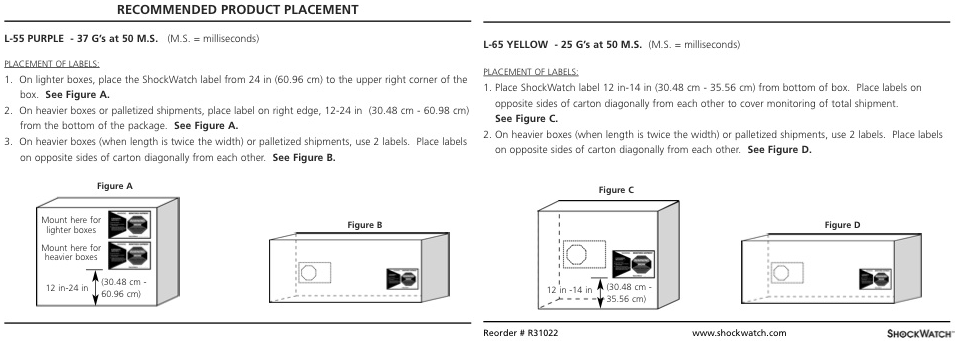

How to Mount a Shockwatch Label

ShockWatch Impact Indicator Clips & Tubes

Quality Assured Safe Transit to your customer’s door!!

ShockWatch impact indicator clips are tamperproof, mechanically activated devices that turn bright red to indicate mishandling. They come in a wide range of impact sensitivities and sizes. In the event of mishandling, they provide tamperproof evidence and document chain of accountability from the first mile to the last.

As part of a company’s Standard Operating Procedures (SOPs), ShockWatch clips are then used to alert the recipient to inspect shipment contents. The products are specifically designed to help manufacturers identify and correct gaps in their processes, test the robustness of packaging, determine the damage boundaries of products, assure product reliability, or reduce warranty abuse.

Clip

Double Clip: Similar to the Single Tubed Clip, this device provides 360° impact detection.

Tube: Designed for use where space is limited. The ShockWatch tube can be incorporated directly into a product’s design.

Multi-G Clip: A version of the Clip product, the ShockWatch Multi-G Clip is a unique, cost-effective shock diagnostic tool for packaging engineers, distribution analysts, product designers, and manufacturing engineers. It is designed for determining package sensitivity during drop testing. The clear, acrylic housing incorporates three tube sensitivities into a single unit to indicate a customizable low, medium, and high sensitivity to impact.

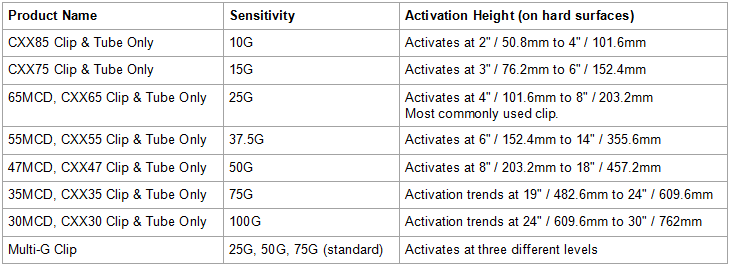

Clips and Tubes Selection Guide

To select the proper shock activation level determine if shock specifications exist for the product to be monitored. Most complex electromechanical products such as hard drives, avionics, analysis instruments, etc., have been through extensive testing to establish shock damage boundary data. When this information is available it simplifies the selection process. If shock specifications do not exist, use the selection table below, based upon your knowledge of product fragility or contact a ShockWatch.co.uk to assist you in selecting the correct sensitivity

Lets Talk!

We are always happy to hear from you regarding questions and/or technical help. Just give us a call on 0207 739 3344 or fill out our form below.