Selection Guides

Shockwatch Labels

Using this selection guide: This selection guide and sensor activation table should always be used as starting point. Packaging design and construction may affect the correlation between drop height and ShockWatch activation.

This guide is for reference only. We recommend that you speak to a ShockWatch representative before placing an order.

Two things you need to know to select a ShockWatch sensitivity:

- Cubic metres of shipment (height x width x depth)

- Weight of shipment

| Weight in Kilograms | .001 – .030 Cubic Metre | .031 – .135 Cubic Metre | .136 – .400 Cubic Metre | .401 – 1.350 Cubic Metre | 1.351 + Cubic Metre |

| 0 – 4.5 | GREEN | GREEN | ORANGE | ORANGE | RED |

| 4.5 – 11.2 | GREEN | ORANGE | ORANGE | RED | RED |

| 11.2 – 23 | ORANGE | ORANGE | RED | RED | PURPLE |

| 23 – 45 | ORANGE | RED | RED | PURPLE | PURPLE |

| 45 – 113 | RED | RED | PURPLE | PURPLE | YELLOW |

| 113 – 450 | RED | PURPLE | PURPLE | YELLOW | YELLOW |

| 450 + | – | PURPLE | YELLOW | YELLOW | YELLOW |

Expected drop height for activation

| Weight | Yellow L65 | Purple L55 | Red L47 | Orange L35 | Green L30 |

| Under 45 Kilograms | – | 0.30 – 0.48 M | 0.30 – 0.60 M | 0.60 – 0.91 M | 0.91 M + |

| Over 45 Kilograms | 0.15 – 0.30 M | 0.20 – 0.40 M | 0.30 – 0.48 M | – | – |

NOTE: Packaging and construction may affect the correlation between drop height and ShockWatch activation. This table is intended as an approximate guide only. Minimal testing is suggested. ShockWatch Label G-Force Guide

| Yellow Label = 25G | |

| Purple Label = 37G | |

| Red Label = 50G | |

| Orange Label = 75G | |

| Green Label = 100G |

Drop Spot Selection Guide

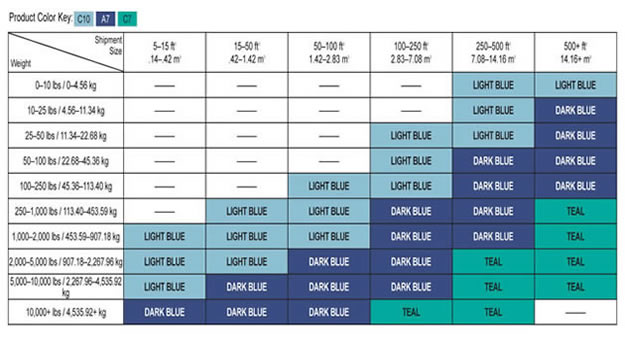

| C10 Light Blue = 25g | |

| A7 Dark Blue = 15g | |

| C7 Teal = 10g |

ShockWatch Clip, Multi-G, and Tube Selection Guide

All product is rated at 50 milliseconds

| MC (Mini Clip), CX (Clip) = both types have one tube MCD (Mini Clip Double), CXX (Clip Double) = both types have two tubes | |||

|---|---|---|---|

Product Name | Sensitivity | Activation Height | Application Examples |

| 85MC, CX85 and CXX85 Clip and Tube only | 10g | Activates at drops on hard surfaces |

|

75MC, CX75 and CXX75 Clip and Tube only | 15g | Activates at 7cm to 15cm drops on hard surfaces |

|

65MC, CX65 and 65MCD, CXX65 Clip and Tube only | 25g | Activates at 10cm to 20cm drops on hard surfaces.Most commonly used clip. |

|

55MC, CX55 and 55MCD, CXX55 Clip and Tube only | 37.5g | Activates at 15cm to 35cm drops on hard surfaces. |

|

47MC, CX47 and 47MCD, CXX47 Clip and Tube only | 50g | Activates at 20cm to 45cm drops on hard surfaces. |

|

35MC, CX35 and 35MCD, CXX35 Clip and Tube only | 75g | Activation trends at 47cm to 61cm drops on hard surfaces. |

|

30MC, CX30 and 30MCD, CXX30 Clip and Tube only | 100g | Activation trends at 61cm to 101cm drops on hard surfaces. |

|

| CX25 and CXX25 Clip and Tube only | 150g | Activation 76cm to 122cm drops on hard surfaces. |

|

| Multi–G Clips | 25g-50g-75g | Activates at three different levels |

|

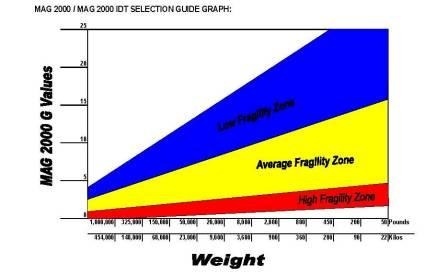

MAG 2000 Selection Guide

o things must be known to select the appropriate indicator:

1. Weight of the shipment

2. Fragility of the shipment–rugged(low), average, or fragile (high)

With these two pieces of information, use the Selection Guide to select the MAG 2000 / MAG 2000 Date/Timer value. For example, a 9,000 kgs. crate that is of average fragility will need a range of MAG devices approx. from 3-8 G. To monitor all planes MAG2000 devices need to be placed on adjacent sides on the shipment

Low Fragility Zone — Applicable in situations in which both visible and hidden damage is possible, and a single extreme impact will cause damage to product. Pertains to products transported via a variety of modes.

Average Fragility Zone — Applicable in situations in which there is a moderate degree of stability and survivability built into the product, and in which a standard mode of transportation is used.

High Fragility Zone — Applicable in situations in which hidden damage is the key concern. Typically, these products will be constructed of low tolerance components such as data storage drives, optical lenses, or any other products that require precise alignment. Pertains to most products that require specialized modes of transportation, such as air-ride vans or extended travel in hydro-cushion railcars.

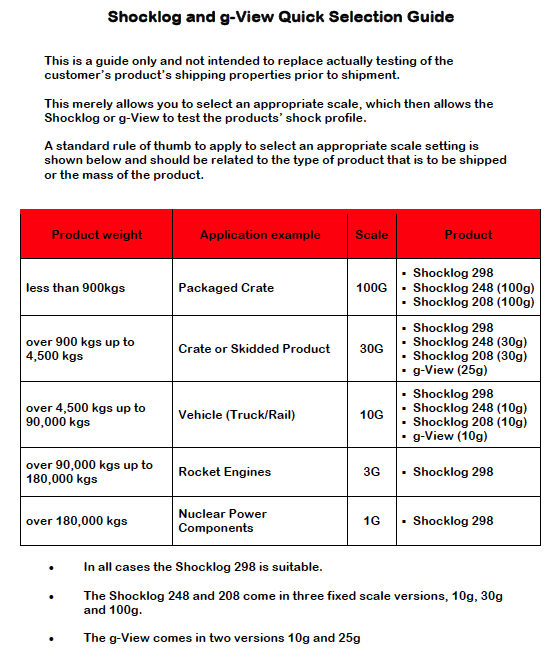

Shocklog and g-View Quick Selection Guide

Lets Talk!

We are always happy to hear from you regarding questions and/or technical help. Just give us a call on 0207 739 3344 or fill out our form below.